Growing Applications of PTFE in the Food Packaging Industry

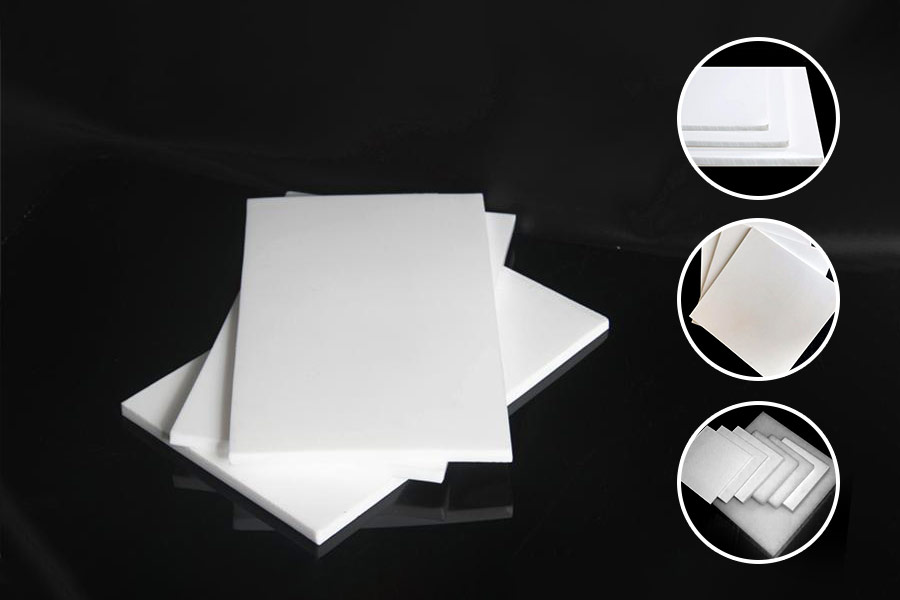

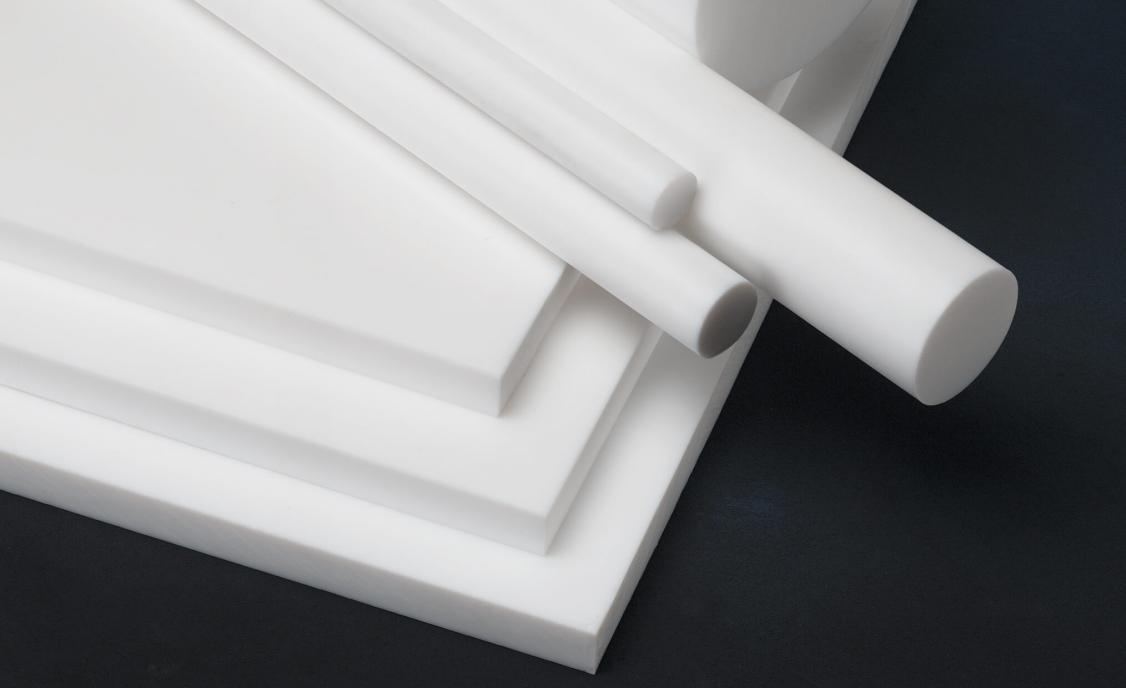

In recent years, polytetrafluoroethylene (PTFE) material has gained increasing attention in the food packaging industry. PTFE, as a high-performance engineering plastic, offers excellent properties such as high temperature resistance, chemical inertness, and low friction coefficient, making it an ideal material for food packaging.

The outstanding characteristics of PTFE have led to its wide-ranging applications in the food packaging sector. Firstly, PTFE exhibits excellent high temperature resistance, enabling it to withstand processes like high-temperature baking and sterilization, ensuring food safety and hygiene. Secondly, PTFE possesses exceptional chemical inertness, preventing any reaction with acids, alkalis, or other substances present in food, thereby preserving the quality and taste of the packaged products. Additionally, the low friction coefficient of PTFE provides excellent slipperiness, facilitating smooth packaging processes.

The demand for PTFE material in the food packaging industry is steadily increasing. More and more food packaging companies are adopting PTFE material to manufacture high-temperature baking bags, baking papers, and oven liners, among other products, to meet the market's demand for high-quality and reliable food packaging. The application of PTFE not only enhances the quality and efficiency of food packaging but also reduces production costs, thereby improving the competitiveness of businesses.

However, as the application of PTFE material expands in the food packaging industry, it is crucial to strengthen quality control and safety regulations. Relevant authorities should enhance qualification audits for PTFE material suppliers, ensuring their products comply with food safety standards. Simultaneously, food packaging companies should strengthen their own quality control systems, ensuring the correct usage and handling of PTFE material to safeguard consumer rights and food safety.

In conclusion, the future prospects for PTFE material in the food packaging industry are promising. By continuously improving material quality and strengthening regulations, PTFE material will bring more innovation and development opportunities to the food packaging industry, enhancing its competitiveness and sustainable growth.