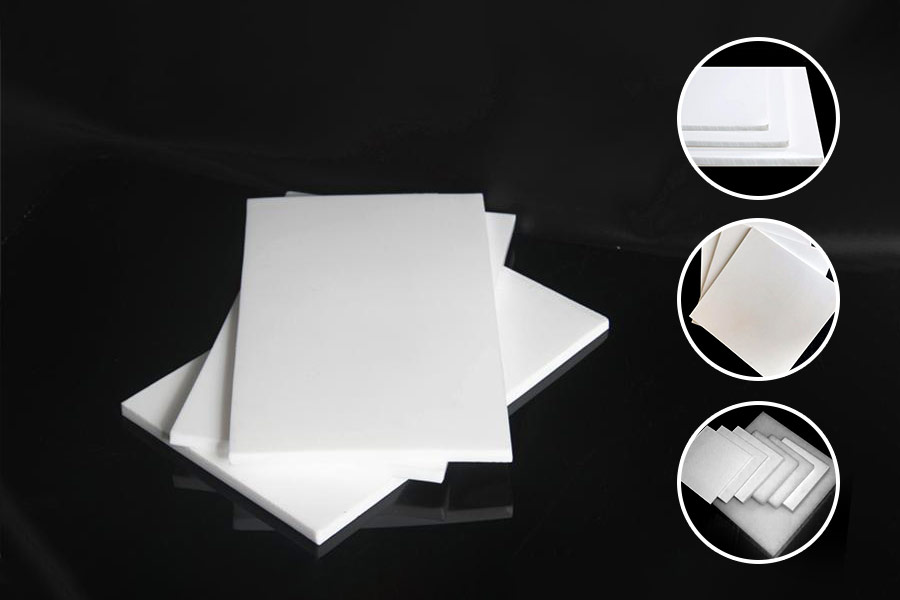

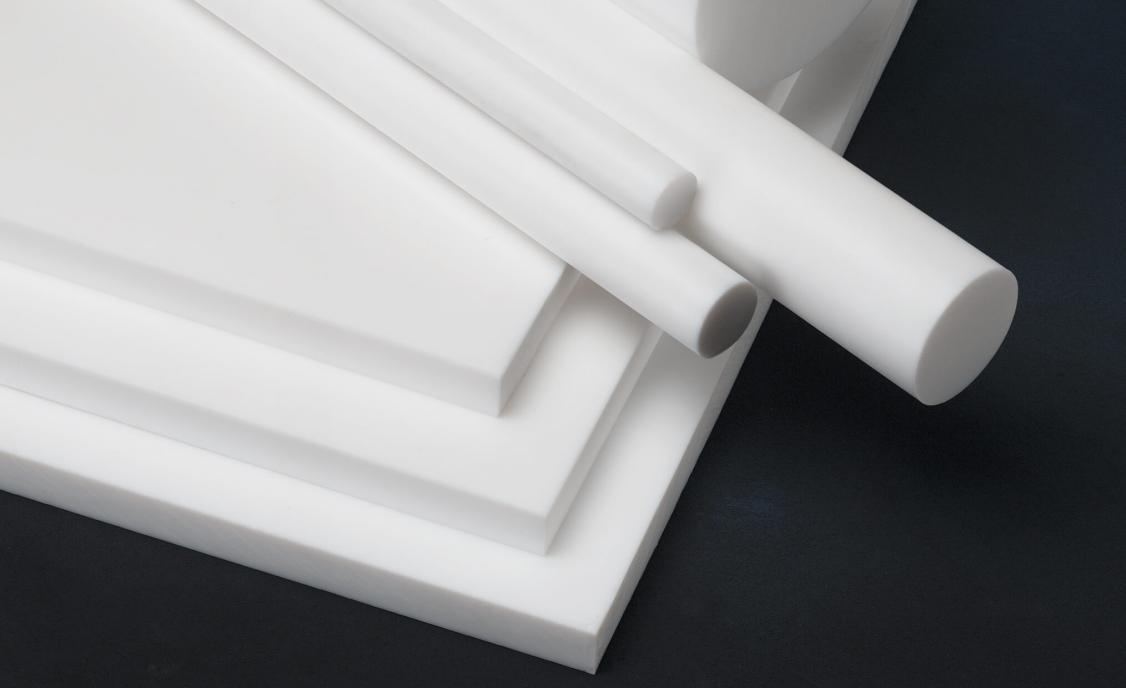

Properties of PTFE Film

1. Material introduction

Polytetrafluoroethylene (PTFE), with the English full name, is a fully fluorinated crystalline thermoplastic plastic. Its molecular formula is [CF2=CF2]-n, and it is commonly abbreviated as PTFE. The resin itself is white in color. PTFE possesses excellent properties such as high and low-temperature resistance, low friction and wear, chemical corrosion resistance, high electrical strength, non-stickiness, and weather resistance. It also exhibits good physical and mechanical properties. PTFE is widely used in various industries. For example, it is used in the electronics industry, particularly in the flat panel display industry, as a consumable material. During the processing and production processes of TFT-LCD, COG, SMT, PDP, etc., the role of PTFE film is to provide high-temperature resistance and impact resistance, preventing glass damage caused by PCB level differences and particles when the driving IC is bonded to the glass using an ACF-Bonding hot press machine.

2. Characteristics:

a. Non-stickiness: Almost all substances do not adhere to PTFE film. Even very thin films exhibit excellent non-stick properties.

b. Heat resistance: PTFE film has excellent heat resistance and low-temperature resistance. It can withstand high temperatures up to 300°C for short periods and can be continuously used between 240°C and 260°C. It demonstrates significant thermal stability, allowing it to operate at freezing temperatures without becoming brittle and not melting at high temperatures.

c. Sliding properties: PTFE film has a low coefficient of friction. The friction coefficient varies during sliding under load, but the values remain between 0.05 and 0.15.

d. Moisture resistance: The surface of PTFE film is non-wetting to water and oil, making it resistant to contamination during production operations. If it becomes slightly dirty, it can be easily wiped clean. Short downtime saves working hours and improves efficiency.

e. Wear resistance: PTFE film exhibits excellent wear resistance under high loads. It combines wear resistance and non-adhesion properties under certain loads.

f.Corrosion resistance: PTFE is virtually unaffected by chemicals and can protect parts from any type of chemical corrosion.

3. Applications:

PTFE film is used as gaskets, sealing materials, and lubricants that work with various media. It is also used as electrical insulation components for various frequencies, such as capacitor dielectrics, wire insulation, and electrical instrument insulation.